OUR COMPETENCIES

Industrialization

As the product range of our customers constantly increases, the need to outsource more and more components, such as wiring systems or even former made in-house electrical systems, is a daily topic for the whole Industry.

KAB CONNECT supports its customers with these needs, by contacting and connecting with them from an early stage, for the proper understanding of all specific custom requirements and specifications, ensuring the best value added.

At the same time, we use our industrialization and project development skills to optimize our manufacturing & logistics systems, assuring that we deliver with the same quality every time and just in time to our customer.

From the cutting process to the final assembly line, we use several production methodologies and some of the newest philosophies and characteristics of a lean management. This ensures that our products are manufactured according to the customer requirements & specifications, always with the same high-quality standard.

The control we have over all processes is the key of an excellent performance right at the first time, improving the product quality, in order to increase KAB CONNECT customers’ satisfaction.

Our core competencies

Once KAB CONNECT is granted with a new project, we start working by defining the best practices to perform what is requested, and this includes using the best engineering processes and production methodologies to achieve the best relation between efficiency, product quality and production output.

For our project management to be successful we use some of the following guidelines and processes:

-

- DEVICES/TOOLS DEVELOPMENT

- SMED

- SPC

- MSA

- SUPPLIER MANAGEMENT

- SUPERMARKET

- KANBAN

- FIFO

For us, quality and ecological environment is everywhere and in everything we do. Either we are dealing with external or internal suppliers, incoming material, handling goods in our warehouse, from every production process step to the final shipment to the customer, we fulfil the best quality and environmental practices demanded by the industry and by the industry and the Quality and Environmental Management Systems (QEMS).

KAB CONNECT is using in a daily basis state-of-the-art quality tools and methodologies, such as:

-

- PPAP

- ISIR/EMPB

- PDCA

- CONTROL PLAN

- 8D

- PARETO

- ISHIKAWA

- RISK AND OPPORTUNITY ANALYSIS

- ANALYSIS OF ENVIRONMENTAL ASPECTS AND IMPACTS

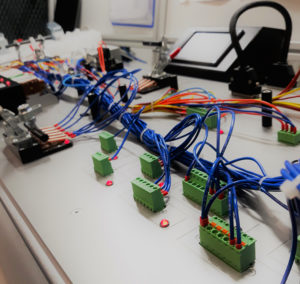

To build wiring systems we make use of the most reliable and efficient equipment and devices. We work with the best equipment manufacturers of the industry to ensure that all production process steps run smoothly:

To build wiring systems we make use of the most reliable and efficient equipment and devices. We work with the best equipment manufacturers of the industry to ensure that all production process steps run smoothly:

-

- cutting

- stripping

- marking

- printing

- crimping

- connecting

- soldering

- assembling

- testing

Nevertheless, as technology is crucial for our business, we know that no matter how far we go with automation technology, we will always depend on our qualified personnel to make daily activities happen and to achieve our targets. Therefore, there is no machine that is more important than a person for us.

Our manufacturing shop floor is prepared and in continuous improvement to achieve the best compromise between target outputs, efficiency, product quality and material flow optimization, simultaneously considering our staff’s health and workplace safety as priorities.

Our manufacturing shop floor is prepared and in continuous improvement to achieve the best compromise between target outputs, efficiency, product quality and material flow optimization, simultaneously considering our staff’s health and workplace safety as priorities.

At KAB CONNECT we use some of trendiest lean production concepts to get things done right at the first time, such as:

-

- 5S

- Fast meeting

- 4-eyes principle

- Product traceability